Seeing a Common Catalyst with New Eyes

Chemical imaging microscope shows corrugated gamma-alumina surface

(January 2013)

The surface of the plate-like particles is far from smooth, according to a new transmission electron microscopy study conducted by Pacific Northwest National Laboratory and the FEI Company.

Results: Neither smooth nor disordered, gamma-alumina nanoparticles are corrugated with tiny pores inside, according to scientists at Pacific Northwest National Laboratory. Using a powerful transmission electron microscope, the team obtained ultrahigh-resolution images and chemical data about the particle's surface. They found that the particles were covered with ridges made from a more open, yet symmetrical, arrangement of atoms. The open arrangement on the surfaces, notated as (110), covers 70% of the nanoparticle.

By understanding the structure and function of tiny gamma-alumina particles, scientists are taking crucial steps to optimizing and realizing new useful properties for these materials. "If we can learn about the surfaces, then we can tailor them and make them more efficient in catalytic applications," said Dr. Libor Kovarik, who led the imaging study as part of PNNL's Chemical Imaging Initiative.

Why It Matters: Reducing refineries' energy demands or car and truck emissions requires efficient catalysts on durable support materials. The supporting material must withstand severe temperature and pressure changes. Gamma-alumina has been studied extensively, but its atomic arrangement has not been established because of the challenge of getting a detailed view of this complex material. Accurately describing the atomic structure is crucial for understanding and taking advantage of the best properties of gamma-alumina.

"Catalytic research demands this type of state-of-the-art chemical imaging research," said Dr. Charles Peden, a heterogeneous catalysis scientist who worked on the study, and an Associate Director of PNNL's Institute for Integrated Catalysis. "Dr. Kovarik's outstanding new images from this powerhouse microscope have yielded unprecedented new information about a catalyst material of enormous practical utility."

Methods: The team began with a novel materials synthesis method, and a new microscope to obtain the images and interpret the associated chemical data. With the synthesis approach, the team produced rhombus-shaped particles of gamma-alumina, Al2O3, that were 30 to 50 nanometers across and 10 to 20 nanometers thick. The team studded the surface of the alumina particles with nano-sized catalytic platinum particles.

They placed these catalyst particles on a grid and inside a specialized cell. The cell was then fit into a microscope that uses a beam of electrons, rather than light, to obtain images. This instrument is a spherical aberration-corrected transmission electron microscope with a high angle annular dark field detector. The team operated the microscope, or TEM, in two different modes, phase contrast and scanning. In this way, they obtained detailed three-dimensional images that could be sliced open with specialized software yielding entirely new views.

"Transmission electron microscopy is the only technique that can provide direct visualization of this complex material. While spectroscopy provides a wealth of information about the chemical bonding environment of atoms on these surfaces, only TEM can give us a direct view and reveal the fine structural features of the material surfaces," said Kovarik.

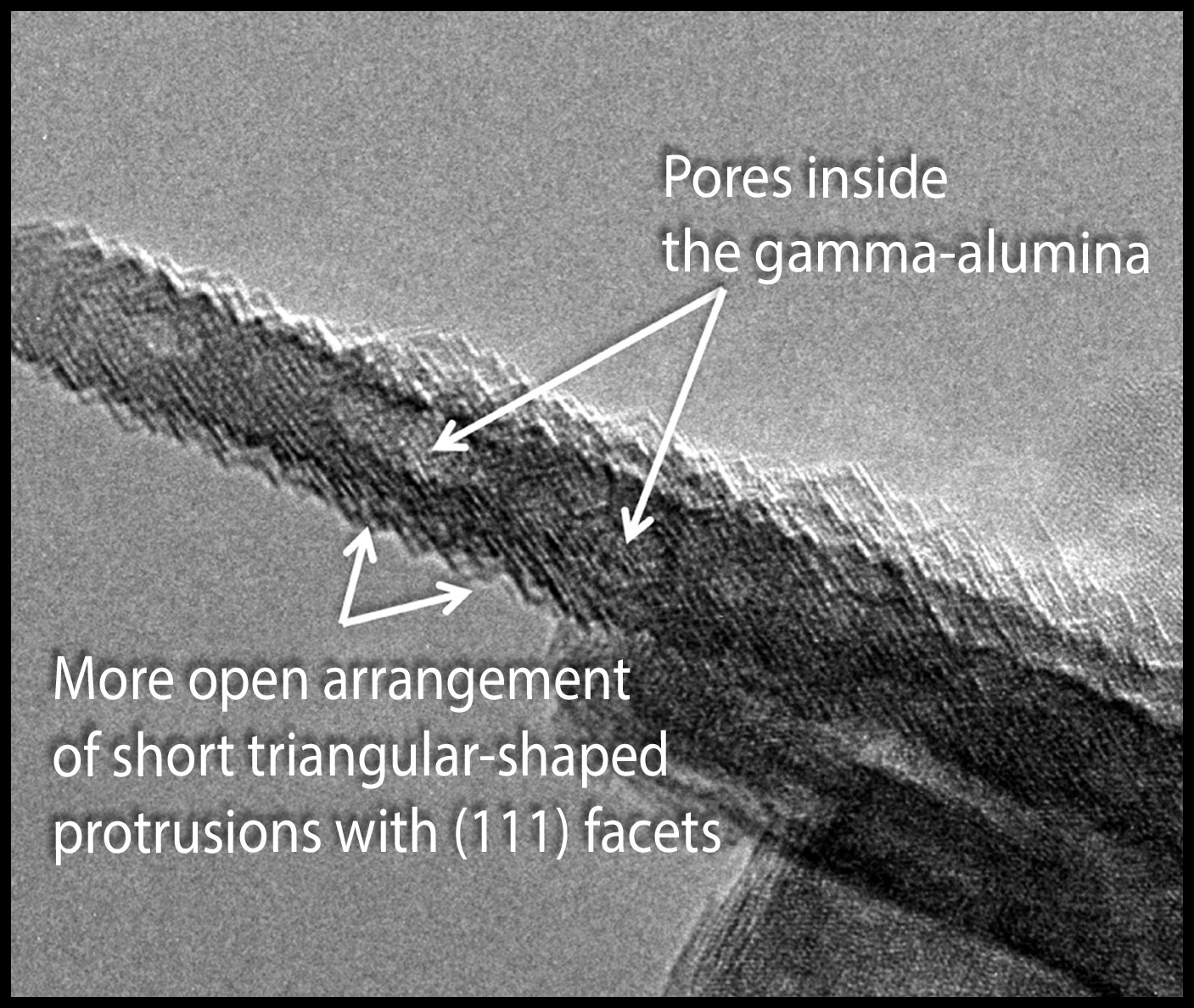

The team found that the surface of the particles was corrugated at the atomic level. The surface is significantly altered during synthesis, with 70% of the relatively flat surface, referred to as (110), turning into a more open arrangement of short triangular-shaped protrusions with (111) facets.

Slicing the TEM images open, the team discovered pores within the plate-like particles. The oblong pores, about 2 to 4 nanometers wide, were spread throughout the material. Surprisingly, the surfaces inside the pores do not have the same structure as those on the outer surfaces of the particles.

"Once you can see and understand a complex system, you can generate a time basis for controlling that system," said Dr. Louis Terminello, who leads the Chemical Imaging Initiative at PNNL.

What's Next? Seeing the corrugated surface and the oblong pores inside the alumina particles gives researchers clues to tailoring the gamma-alumina and other types of catalyst support particles. This work is part of a larger effort to elucidate the electronic and atomic structure of catalysts and energy storage materials.

Acknowledgments:

Sponsors: Libor Kovarik, Chongmin Wang, and Annie Qiu were funded by the Chemical Imaging Initiative, supported by the Pacific Northwest National Laboratory Directed Research and Development Program. Charles HF Peden, János Szanyi, and Ja Hun Kwak were funded by the Department of Energy Office of Basic Energy Sciences' Chemical Sciences, Geosciences, and Biosciences Division.

User Facility: Environmental Molecular Sciences Laboratory

Research Areas: Chemical Imaging and Chemical Sciences

Research Team: Libor Kovarik, Chongmin Wang, Annie Qiu, Charles HF Peden, János Szanyi, and Ja Hun Kwak, PNNL; Arda Genc, FEI Company

Reference: Kovarik L, A Genc, C Wang, A Qiu, CHF Peden, J Szanyi, and JH Kwak. 2013. "Tomography and High-Resolution Electron Microscopy Study of Surfaces and Porosity in a Plate-like γ-Al2O3." The Journal of Physical Chemistry C 117(1):179-186. DOI: 10.1021/jp306800h