A Solid Cold Solution

A catch-and-release solid-state fuel cell material operates coolly

(November 2010)

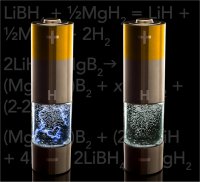

The hydrogen catch-and-release, a.k.a. dehydrogenation and hydrogenation, in this LiBH4 and MgH2 fuel cell system operates coolly and reversibly. Enlarge Image

Results: Using a catch-and-release method of swapping out hydrogen atoms, scientists at Pacific Northwest National Laboratory and the University of Connecticut have tested a solid-state hydrogen storage material that operates at low temperatures. Scientists improved the dynamics of the reversible system at a significantly lower temperature by employing additives and a mechanical process called "ball milling." These results tackle two prime objectives for improving the performance and safety of hydrogen fuel cells: lower the temperature and increase the storage capacity.

Why it matters: Finding a practical fuel cell technology requires the development of an onboard fuel storage system that operates in a safe and efficient manner. In this study of one hydrogen fuel cell system, scientists sought to understand the mechanism of a reversible method of dehydrogenation and hydrogenation, the "catch-and-release" of hydrogen fuel to create a constant current in the fuel cell. One disadvantage: the material they chose to study must be heated to extremely high temperatures for this process to occur. By employing additives and a mechanical technique, somewhat like very small-scale rock tumbling called "ball milling," they found that they could reduce the temperature of the reaction. The results promote our understanding of applying additives and mechanical methods to optimize solid-state hydrogen storage for fuel cells.

Methods: Two primary objectives prevail in creating an efficient and cost-effective hydrogen fuel cell: find a mechanism that keeps the hydrogen catch-and-release temperatures low and develop a safe, high-capacity onboard hydrogen storage system. For 2015, the U.S. Department of Energy (DOE) set a goal for hydrogen storage in an automobile: 6 wt% hydrogen with an operating temperature of less than 100 °C. Although hydrogen in a liquid form has the highest volumetric density, this form requires both high pressure and cooling below hydrogen's Critical point. For example, for hydrogen to be in a full liquid state without boiling off it needs to be cooled to 20.28 K (-423.17 °F/-252.87°C) while still pressurized, which is not practical or safe for a commercially viable vehicle. Using a solid-state hydrogen storage material might be a practical way to meet DOE's performance goal.

For this research, the scientists studied a promising material and system for solid-state storage that employs a hydrogenation process: in effect, catching and releasing the hydrogen atoms to provide fuel for the operation of fuel cells. The material is lithium borohydride (LiBH4) with a dash of the additive magnesium hydride (MgH2). Using the ball-milling process along with the additive improves the dynamics of the system so that the charging-discharging action occurs at a higher speed, but without high temperatures. This material also provides high-density hydrogen storage, making the system more efficient. Higher density hydrogen storage means less frequent refueling.

Fine-tuning for optimal performance of the material and process was essential, so the scientists used a nuclear magnetic resonance (NMR) spectrometer and other resources at EMSL to study the reaction at the molecular level. Another prime characteristic of this mechanism is that the material can be reloaded with hydrogen. In the absence of high temperatures in the reaction, this solid-state storage material retains its storage capacity for use over and over.

What's Next: The research points to new avenues of study in additives and mechanical manipulation to increase the efficacy of hydrogen storage for fuel cells.

Acknowledgments: This research was supported by the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy Fuel Cell Technologies Program and was performed by Leon L. Shaw and Xuefei Wan of the University of Connecticut, and Jian Zhi Hu, Ja Hun Kwak, and Zhenguo Yang of Pacific Northwest National Laboratory.

The team used the 900-MHz NMR spectrometer at Department of Energy's EMSL, a national scientific user facility at PNNL.

Reference: Shaw L, X Wan, JZ Hu, JH Kwak, and Z Yang. 2010. "Solid-State Hydriding Mechanism in the LiBH4 + MgH2 System." Journal of Physical Chemistry C. 114(17):8089-8098. DOI: 10.1021/jp1003837.