Energy Everywhere—A Big Idea Evolution

By Robert Weber

Feedstocks for renewable fuels have evolved over the past two decades in response to economic, social justice (e.g., the food vs. fuel controversy), and environmental (e.g., the water-fuel nexus) demands associated with diverting huge quantities of resources needed to substitute even small fractions of our annual demand for petroleum. The changes have also reflected our increasing command over technology available for converting feedstocks that are not particularly energy dense (<20 MJ/kg) into gasoline-like and diesel-like fuels (>40 MJ/kg). Yet, the renewable fuels industry is still nascent, reliant on government subsidies rather than supply/demand economics, for sustained profitability. Subsidies and mandates are still required because the feedstocks are expensive and difficult to convert, and the market does not yet sufficiently value sustainability.

In 2016, Pacific Northwest National Laboratory and Ames Laboratory organized a series of three workshops that explored extending the progression of feedstocks to materials currently discarded or economically stranded. Converting those feedstocks could, in some cases, solve two problems concurrently—energy production and obviating waste. Using waste feedstocks would also help slow encroachment on domestic prairie lands of purposely grown biomass.

Energy Everywhere, a "Big Idea" now being constructed for consideration by the U.S. Department of Energy considers a different approach: small-scale conversion of biomass, replicated and distributed, to match the geographic and temporal distribution of the waste, combined with collection and central processing of the intermediate fuel precursors. Previous analyses have shown benefits to such an approach but have been based on conversion processes that rely on access to large markets for co-product disposal and supplying utilities. The workshops identified a new opportunity—mass manufacture of hundreds to thousands of small, modular plants, which benefit from the economies of mass manufacturing rather than scaling.

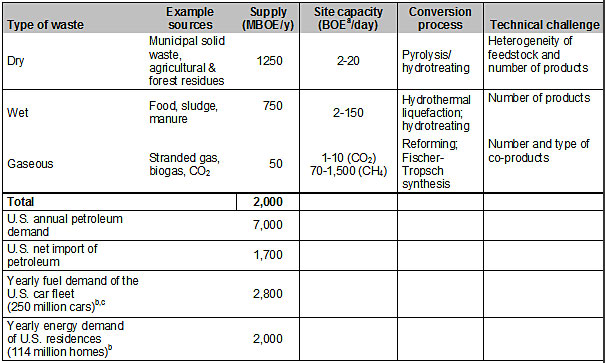

The feedstocks under consideration span three states of matter: gases (natural gas and concentrated carbon dioxide), suspensions (food waste, algae, sewage sludge), and solids (municipal solid wastes, agricultural and forest residues). In total, those feedstocks can be converted into fuel precursors with heating value equivalent to ~30 percent of the ~7 billion barrels of petroleum used annually in the United States (Table 1). This is larger than the net imports of petroleum by the United States (ca. 2016) and enough to satisfy about half of the combined, annual demand of the entire U.S. fleet of cars and all residences.

Table 1. Stranded, dispersed carbon in the United States comes in three broad categories.

The realization of Energy Everywhere requires research on small-scale conversion and the availability of the value chain that will manufacture and operate the facilities and valorize the products. Notably, the conversion will require technology that can deal with heterogeneous inputs—even sorted waste contains many extraneous materials—in locations far from industrial infrastructure that could supply utilities or accept co-products. Moreover, the delivery rate of the feedstock will necessarily be much smaller than that considered for biorefineries: waste resources are available at the equivalent of less than 100 barrels of oil per day instead of greater than 10,000 barrels per day needed to supply a large bio-refinery following the usual 0.7-power law scaling of the chemical and petroleum industries. For reference, the ~140 petroleum refineries in the United States process 150,000-500,000 barrels per day.

- BOE = barrel of oil equivalent = 6.1 GJ of heating value.

- Energy estimates from U.S. Energy Information Agency Annual Energy Outlook 2015, 2015.

- Vehicle estimate from U.S. Department of Transportation Transportation in the US 2013, 2013.

Leadership

The CTI is led by PNNL scientist John Holladay, who has organized and led several large consortia and multi-partner projects at the lab. His research centers on catalysis, with a primary focus on condensed-phase systems composed of complex oxygenated mixtures. The initiative's chief scientist, Johannes Lercher, is a recognized international leader in heterogeneous catalysis, the author of over 500 papers, and director of the Institute for Integrated Catalysis at PNNL. PNNL scientist Roger Rousseau will undertake the essential task of integrating basic and applied research teams within the CTI.

The entire initiative team met with an external review committee in August and received resounding praise for their proposed integrated research program. This included recognition of the careful and deep planning that developed this initiative from an excellent set of individual ideas to a fully integrated LDRD program.

Complementing chemical conversions research

The CTI fulfills a major goal of PNNL's objective, Chemical Conversions for Carbon-Neutral Energy, where we recognize the need to control catalysts that enable chemical transformations at unprecedented reaction rates, while demonstrating catalyst breakthroughs enabling new conversion platforms with improved efficiency. The transformational science need identified by this laboratory objective, and embraced by the CTI, is to increase the rates of lower temperature catalytic processes to achieve rates and precision of conversion we cannot yet reach with today's technologies and strategies.

The key for the CTI is taking inspiration from biological systems for enabling low-temperature catalysis, thereby connecting basic and applied science through focusing on common problems and teaming across research directorates and the entire laboratory, as well as with important academic, industrial, and national laboratory partners. A perfect example of our teaming efforts is demonstrated by the Energy Everywhere Big Idea, described in the accompanying article by PNNL scientist Robert Weber.

__________________1Bergin, SP. Annual Report for the Fischer-Tropsch Fuels Production and Demonstration Project Agreement Number DE-FC26-01NT41099, 2003.

2U.S. Department of Agriculture. Carbon Prices and the Adoption of Methane Digesters on Dairy and Hog Farms, 2011.

Dr. Robert (Bob) Weber leads research activities in heterogeneous catalysis for the Institute for Integrated Catalysis and manages the commercial business sector for the Physical and Computational Sciences Directorate at Pacific Northwest National Laboratory.